What is the different welding methods of stainless steel

Welding of Stainless Steel

The ‘300 series’ austenitic stainless steels are readily welded with or without filler wire

They are by far the most common types used in fabrications.

Superaustenitic, ferritic, superferritic, martensitic and ferritic-austenitic (duplex/super

duplex) material types require more control when being welded and may involve post weld

heat treatment or special welding consumables.

The prime objectives when producing a welded joint are: -

1. To ensure sound welds which match the corrosion and mechanical properties of the

parent material.

2. To choose a welding process that meets productivity requirements, but which will

result in as little distortion as possible and need a minimum of post weld dressing.

Considerations to be taken when choosing a Welding Process are: -

• Joint type and material thickness

• Welding position and working environment e.g. fabrication shop or on-site

• Manual or mechanised methods to increase productivity and repeatable quality

• Availability of suitable filler materials which are often over-alloyed to enhance the

corrosion resistance of the weld deposit, and may be essential in the prevention of

weld bead cracking.

The most popular welding processes used on stainless steels are: -

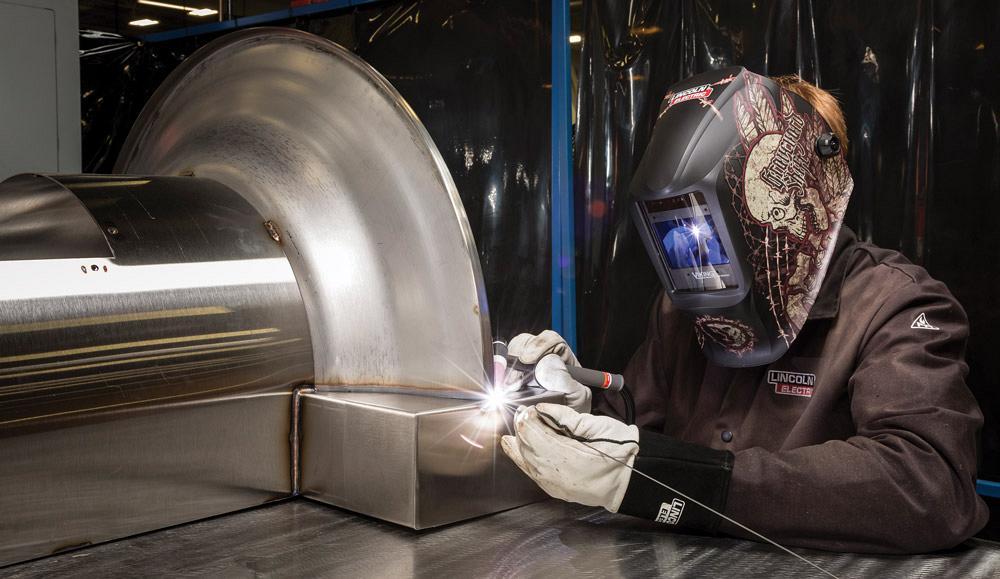

Gas Tungsten Arc Welding (GTAW or TIG)

This is the most widely used process due to its versatility, high quality and aesthetic

appearance of the finished weld. The ability to weld at low current, and hence low heat

input, plus the ability to add filler wire when required, make it ideal for thin materials and

root runs in one sided welding of thicker plate and pipe. The process is easily mechanised

and the ability to weld with or without the addition of filler wire (autogenous welding) make

it the process for orbital welding of fixed pipe. Pure argon is the most popular shielding

gas, but argon rich mixtures with the addition of hydrogen, helium or nitrogen are also

employed for specific purposes. Inert backing gas protection of the weld under bead is

employed with single sided welding to prevent oxidation and the loss of corrosion

resistance.

Plasma Arc Welding (PAW)

A derivative of the TIG process involving a constructed nozzle system to produce a narrow

concentrated transferred plasma arc with deep penetration characteristics. Mainly used in

a mechanised system where high speed, high productivity autogenous welding of square

edged butt joints up to 8mm thick is required. With thicker square edged butt joints, a

combination of PAW/TIG and filler wire becomes necessary to ensure a full profile weld

surface. Thickneses greater than 10mm employ a partial v-preparation, PAW root weld

followed by multi-pass joint filling. Argon backing gas protection is necessary to maintain

the corrosion resistance of the under bead.

Shielded Metal Arc Welding (SMAW or MMA)

Manual in operation and the oldest of the arc processes, MMA electrodes are in common

use due to their flexibility in accommodating the wide range of materials to be welded.

Electrode coating types are produced to give performance characteristics, which lend

themselves suitable for differing welding applications. The most widely used, acid rutile

coated electrodes produce a spray arc type metal transfer, self-releasing slag and a finely

rippled aesthetic weld profile. These electrodes are designed to produce a spray arc type

transfer of the weld metal, a self-releasing slag, a fine rippled bead and an aesthetic

looking weld. Minimal post weld dressing will be required. They are primarily used in the

down hand position when producing fillet and butt welds. Electrodes with this coating type

can be used in position but are limited in application and size i.e. 3.2mm maximum.

Basic coated electrodes produce weld metal of higher integrity, with slag micro-inclusions

and gas pores, and are extremely useful for fixed pipe weldments. Slag removal and weld

profiles are not as attractive as with the acid rutile types. Special coated electrodes are

produced for specific applications; e.g. vertical-down and high recovery downhand

welding. Electrodes are manufactured in sizes ranging from 2.5 to 5.0mm in diameter

(308L,347 and 316Ltypesalso in 1.6 and 2mm diameters)

Gas Metal Arc Welding (GMAW or MIG/MAG)

This semi-automatic welding process, which can be used manually or automated, involves

a continuous consumable solid wire electrode and an argon rich shielding gas. It is

employed for its high productivity features when welding thin material using ‘short-circuit’

metal transfer mode, or ‘spray arc’ transfer with thicker material. Power sources, which

produce a pulsed current supply have been developed to provide improved weld metal

quality when positional welding, and cleaner weld appearance. Gas mixtures, with the

addition of oxygen, helium, carbon dioxide etc have been developed to improve arc

stability and weld bead ‘wetting’ characteristics.

Flux Cored Arc Welding (FCAW or FCW)

A version of the MIG/MAG process where the solid wire consumable is replaced with a flux

(FCW) or metal powder (MCW) filled tubular wire and can be used with equipment of the

same type. Two variants of wire are produced, one to provide all positional capabilities

and one for higher deposition down hand welding applications. Higher rates of weld

deposition and weld metal overlaying are possible than with the MMA or MIG/MAG

process. Significant reduction in post weld cleaning and dressing is possible.

Submerged Arc Welding (SAW)

A fully mechanised wire and flux powder shielded arc process capable of high deposition

rate, fast travel speed and weld quality. Applications include continuous down hand fillet

and butt welds in thicker section plate, pipe and vessels and also stainless steel cladding

of mild steel components, particularly where long seams or extended runs are involved.

An electroslag process, employing a strip electrode, is also available for overlaying, having

some characteristics which are superior to SAW.

Electric Resistance Welding (ERW)

Resistance spot and seam welding is generally confined to mass production welding of

thinner material, where the overlap joint type of weld configuration, and the resultant

crevice will not detract from any corrosion resistance expected during service.

Laser Welding

The energy concentration reached in the focused spot of a laser beam is very intense and

is capable of producing deep penetration welds in thick section stainless steel, with

minimal component distortion. The process employs high capital cost equipment and its

use is reserved for mass production manufacturing.